Adient expertly balances a sustainable manufacturing approach with innovations that meet the needs of its customers and the broader automotive seating industry. We sit down with Stewart Johnstone, Vice President Asia.

DRIVING APAC’S AUTOMOTIVE SEATING FORWARD

The automotive industry in the Asia Pacific (APAC) region has undergone a significant transformation in recent years, witnessing a convergence of the automotive, energy, and digital sectors, which is shaping the competitive landscape.

This has opened the door to a diverse range of industry players; new energy vehicle (NEV) makers have gained a meaningful market share, whilst more Asian original equipment manufacturers (OEMs) are expanding aggressively into new regions.

For Tier 1 suppliers, responding to these shifts requires adaption on both the product and service front.

“From a product perspective, it’s essential to align with the electrification and smartification trends” opens Stewart Johnstone, Vice President Asia for Adient, a global leader in automotive seating.

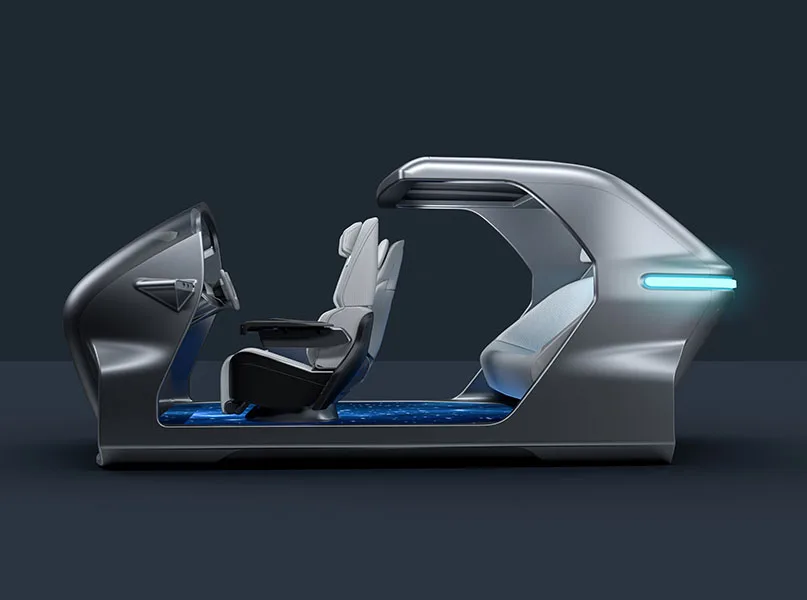

“We’re continually rethinking seat systems for electrified platforms, focusing on comfort, smart features, sustainability, and modularity to accommodate battery layouts and evolving cabin experiences.”

As a long-term, truly global player in the automotive seating sector, the company provides complete seating systems as well as key components such as seat structures and mechanisms, foam and trim, and comfort technologies including pneumatic and mechanical massage systems.

Adient has a presence in 29 countries with more than 200 manufacturing facilities and over 65,000 team members worldwide.

In APAC specifically, the company’s footprint spans China, Japan, South Korea, Thailand, Malaysia, India and Indonesia, with 60+ manufacturing sites and approximately 25,000 employees.

Adient’s main client base includes most major global automotive OEMs as well as leading regional OEMs.

“We’re proud to support all of them with innovative seating solutions tailored to the evolving needs of the industry,” Johnstone smiles.

A STRATEGIC COLLABORATOR

Adient is distinguished by its varied customer base across different OEM types and geographies. This diversity grants the company first-hand insights into industry trends.

“Adient acts as a trusted partner for customers in APAC and our knowledge source strengthens our relationships and positions us as more than just a supplier – we’re a strategic collaborator.”

The company further stands out thanks to its commitment to product innovation, which it has consistently delivered to meet evolving market needs.

Since FY24, Adient commercialised more than 20 innovative products in APAC, such as ProForce Massage, and foot massage functionality.

“These innovations are not developed in isolation; they’re co-created with electric vehicle (EV) makers in mind to address the diverse needs of end users,” he urges.

To sustain its leading position, Adient continues to invest heavily in its engineering capabilities. A recent example is the expansion of its China Technical Centre in Chongqing, completed in 2025.

The upgraded facility is now a best-in-class engineering centre with the latest generation of sled test lab and multi-axis simulation table (MAST) systems, significantly enhancing the company’s design, testing, validation, and product development expertise in China.

Furthermore, Adient’s broad operational footprint gives it a unique advantage, allowing the company to support customers wherever they are.

In fact, many of Adient’s plants are strategically located next to OEMs who operate on a just-in-time (JIT) delivery system. This ensures smooth delivery, reduced logistics costs, and better day-to-day communication.

“This presence isn’t just about geography; it’s about connectivity. We make communication seamless by transferring knowledge internally from one region to another, especially for similar or shared vehicle platforms,” Johnstone tell us.

“Our ability to bridge markets and share expertise ensures consistency, speed, and confidence for our customers, no matter where they operate.”

“Our ability to bridge markets and share expertise ensures consistency, speed, and confidence for our customers, no matter where they operate”

Stewart Johnstone, Vice President Asia, Adient

INVESTING IN INNOVATION

Growth in Asia is high on Adient’s list of priorities, whilst localisation has been one of the strategic levers of the company’s development over the last few years, having successfully established highly automated assembly and stamping lines for critical seat manufacturing.

The company has historically secured new programmes through innovations and continues to do so, having recently partnered with Autoliv to co-develop an advanced safety solution that significantly enhances occupant protection in deeply reclined ‘zero gravity’ seating positions – a feature increasingly popular in premium EVs.

Greater investment into artificial intelligence (AI) and automation is equally core to the company’s growth strategy.

“This will help to drive operational excellence – improving quality, reducing costs, enhancing process transparency, and providing real-time data insights.”

As a JIT business, the company is also working on operational footprint optimisation, which is critical to supporting its OEM partnerships.

“This year, we are executing relocation in two high-growth markets, continuing our journey to optimise and deliver the best footprint solutions for customers.”

LOCALISED APPROACH, GLOBAL STANDARDS

With strong partnerships being central to the company, Adient’s supply chain operations across APAC are designed to deliver agility, resilience, and customer-centricity across a highly diverse and dynamic region.

The company operates through country-specific supply chain teams that understand local market nuances, regulatory requirements, and logistics challenges. This approach ensures Adient can respond quickly to OEM demands whilst maintaining global standards of quality and efficiency.

At the factory level, plant managers play a critical role in driving operational excellence, overseeing production schedules and ensuring that customer commitments are met without compromise.

“Together, these roles form the backbone of our manufacturing ecosystem, enabling seamless integration from procurement to delivery.”

Adient’s external supply chain strategy also emphasises risk mitigation, sustainability, and digitalisation.

“By leveraging advanced planning tools and real-time data analytics, we can anticipate disruptions, optimise transportation routes, and reduce our carbon footprint. This combination of global best practices and local expertise allows Adient to consistently meet clients’ needs across APAC,” Johnstone assures.

“Additionally, we are investing in green logistics initiatives, such as optimising packaging and reducing emissions in transportation to align with OEM sustainability goals.”

“By scaling renewables and deepening partnerships, we advance APAC’s transition to a low-carbon future whilst contributing to global emissions reductions”

Stewart Johnstone, Vice President Asia, Adient

ACCELERATING THE GREEN TRANSITION

AdAdient’s corporate social responsibility (CSR) practices centre around environmental stewardship and value-chain collaboration, supporting its global mission to mitigate climate impact.

A core priority is reducing greenhouse gas (GHG) emissions, which is tracked quarterly under the GHG Protocol guidelines.

The APAC region aligns with global sustainability goals: a 75 percent cut in Scope 1 and 2 emissions by 2030, 35 percent in Scope 3, and utilising 100 percent renewable electricity by 2035.

Progress is measured through a financial control framework across all APAC sites, with third-party verification.

Four pillars drive sustainability across APAC: sustainable manufacturing, a sustainable supply chain, sustainable product design, and employee engagement.

In FY24, 22 percent of regional electricity came from renewables, supported by local partnerships and over 400 continuous improvement projects, delivering a seven percent reduction in electricity-related emissions. Rooftop solar projects further enhance self-sufficiency.

In Scope 3, Adient continues to refine its calculation methodology to provide accurate and transparent data. The company is committed to providing its customers with low-carbon product solutions to drive down the emissions of the entire value chain.

“Collaboration, local action, and accountability define our approach,” notes Johnstone.

“By scaling renewables and deepening partnerships, we advance APAC’s transition to a low-carbon future whilst contributing to global emissions reductions.”

Looking ahead, Adient’s priorities focus on four key areas – people, business sustainability, operational excellence, and customer loyalty. “These priorities position us to navigate industry challenges whilst creating long-term value for our customers and stakeholders,” Johnstone concludes.