Chart Industries is a global leader in the design, engineering, and manufacturing of process technologies and equipment for gas and liquid molecule handling for the Nexus of Clean™ – clean power, clean water, clean food, and clean industrials, regardless of molecule. We take a deep dive into the company’s incredible story with CEO, Jillian Evanko.

- COOLER BY DESIGN

- A VAST AND VARIED CAREER

- EXCEPTIONAL LEADERSHIP

- AN INDUSTRY FULL OF POTENTIAL

- THE CORE STRENGTH OF THE COMPANY

- BUILT TO LAST

- CRYOGENIC TRANSPORT TRAILERS

- NITRO INNOVATION

- SOCIAL SUSTAINABILITY

- UNVEILING TEDDY 2

- BREAKING RECORDS AT SEA

- BUSINESS EXCELLENCE

- CHART’S ONGOING PROJECTS

- AEROSPACE HAS LIFT OFF

- GOING WITH THE FLOW

- STRATEGIC AND FINANCIAL BENEFITS

- DEDICATED TO SUSTAINABILITY

- ONE COHESIVE TEAM

- RESPONSIBLE OPERATIONS

- FUTURE BUILDING

- CHART INDUSTRIES PARTNERS

COOLER BY DESIGN

Molecules are the fundamental building blocks of countless substances and form the basis of chemistry as we know it.

These tiny groups of atoms are fundamental to understanding the world, from the smallest components of life to the immense vastness of the universe.

Helping a worldwide network of customers navigate the entire molecular value chain, Chart Industries (Chart) (NYSE: GTLS) is paving the way in the provision of equipment and solutions for the energy and industrial gas markets.

Chart has worked tirelessly to establish itself as a global leader in the design, engineering, and manufacturing of process technologies and equipment for gas and liquid molecule handling, for what it affectionately refers to as the ‘Nexus of Clean’ – a commitment to clean power, water, food, and industrials.

The incredible work being pioneered by Chart includes enabling the complex production of a molecule itself.

A prime example is the process of creating liquefied natural gas (LNG), where customers use the company’s equipment such as brazed aluminum heat exchangers or its process technology – Integrated Pre-cooled Single Mixed Refrigerant® (IPSMR®) – in order to produce that specific molecule.

Chart then helps its clients to handle the safe transportation of the molecules across a variety of methods, each specific to the individual requirements of the product and the conditions in which they must be kept.

As such, the company’s unique portfolio of products and solutions across stationary and rotating equipment is used in every phase of the liquid gas supply chain, including engineering and service and repair, as well as from installation to preventive maintenance and digital monitoring.

Now utilizing an impressive 64 manufacturing locations and over 50 service centers globally, along with approximately 11,700 dedicated team members, Chart provides industry-leading technology, equipment, and services related to LNG, hydrogen, biogas, and carbon dioxide (CO2) capture, amongst other applications.

“Our unique product portfolio is used throughout the liquid gas supply chain in the production, storage, distribution and end-use of atmospheric, hydrocarbon, and industrial gases,” introduces CEO, Jillian Evanko.

“We now leverage domestic operations located across the US and enjoy an international presence in Asia, Australia, Europe, and Latin America,” she informs us.

The company’s impressive global scope and expanding geographical presence continues to level up and develop alongside the broader energy and industrial gas sector, positioning Chart at the forefront of this burgeoning industry.

A VAST AND VARIED CAREER

Evanko didn’t set out to build a career in industrial manufacturing, but once she got into the space, she never looked back.

“My formal education is in finance, and I started my career at accounting firm, Arthur Andersen – just before the Enron scandal shifted the entire landscape. That unexpected turn pushed me to take a role at Honeywell, where I got my first exposure to industrial operations,” she recalls.

“I quickly realized how energizing it was to be part of something tangible – to build, solve problems, and work with incredibly smart, hands-on teams in the field.”

Since then, Evanko has held numerous leadership roles across finance, operations, and strategy.

“I’ve always been drawn to industries where you can see the real-world impact of your work. That’s what continues to motivate me every day,” she enthuses.

Serving as CEO since June 2018, Evanko initially joined Chart in February 2017 as Chief Financial Officer (CFO).

Prior to joining the company, she was CFO of Truck-Lite and held multiple operational and financial executive positions at Dover Corporation and its subsidiaries.

Before this, Evanko held financial and operational roles at both Honeywell and Sony Corporation.

“I quickly realized how energizing it was to be part of something tangible – to build, solve problems, and work with incredibly smart, hands-on teams in the field”

Jillian Evanko, CEO, Chart Industries

Now, in addition to her role at Chart, she also serves as an independent Director of the Board at Parker Hannifin Corporation.

EXCEPTIONAL LEADERSHIP

As recognition of her hard work and exceptional service throughout the industry, in both 2022 and 2023, Evanko was named as one of the Hydrogen Economist’s ‘Top 50 Women in Hydrogen’, as well as making it onto Hart Energy’s ‘25 Most Influential Women in Energy’ list for 2021.

However, despite these numerous prestigious accolades, Evanko cites her proudest workplace accomplishment as being part of an exceptional team at Chart.

“Because of every dedicated member of staff that I’ve had the pleasure to work with across the entire spectrum of our operations, I’ve always enjoyed the immense privilege of leading an amazingly talented team and an awesome company that has more than doubled in size, entered new markets, and shifted its portfolio,” she prides.

Under Evanko’s exceptional leadership since 2018, Chart has worked toward clean energy and sustainability goals, joining the UN Global Compact, a voluntary initiative to implement sustainability principles, and initiating strategic acquisitions that has allowed the company to significantly expand its product offerings.

Additionally, in this time, Chart made the decision to take calculated risks that previously would’ve been viewed as too hazardous or something that no one else wanted to do.

However, she believes these types of decisions are critical to give businesses such as Chart an advantage in such a competitive environment.

Meanwhile, as a leading female executive navigating the twists and turns of a male-dominated industry, Evanko firmly believes her gender shouldn’t be seen as a defining issue.

“I just aim be the best CEO, not the best female CEO,” she affirms.

“I would say 100 percent of the accolades that I’ve been lucky enough to receive to date are the result of my incredible team. It’s really a credit to the people out there that are designing and building our products.”

Evanko also stresses the vital importance of being a responsible leader, which is why to this day she answers every message she gets, from a conversation on LinkedIn to a text or email.

“At the heart of the company, we want to profitably grow, and we want to continue to deliver unique solutions, but I never want any one of our team members or customers to walk away and say that I wasn’t a kind leader who had no time for her staff,” she muses.

AN INDUSTRY FULL OF POTENTIAL

Across the globe, a multitude of trends across the industrial manufacturing and energy sectors are always fluctuating.

Evanko views both these industries as exciting and full of potential regarding both the domestic US market and on a more global basis.

“The US energy sector is currently balancing two key forces – rising demand and the need for greater flexibility,” she comments.

“Right now, we’re seeing a renewed focus on energy security and a strong role for LNG as a reliable, lower-carbon option that can be deployed quickly and at scale. LNG continues to be a critical part of the equation.”

For Chart, what’s clear is that the path forward won’t be linear, and no single energy source will solve everything for everyone.

“That’s why our molecule-agnostic approach is so important. We’re not tied to one fuel or technology – we enable the infrastructure behind a broad range of solutions,” asserts Evanko.

This includes solutions across industries such as energy, industrial, power generation, LNG, nuclear, water, chemical, space, industrial gas, carbon capture, and hydrogen – to name a few.

“Our focus is on delivering flexible, scalable systems that help our customers adapt and lead – no matter where they are on their energy or sustainability journey,” she lays out.

Backed by its 158 years of experience in designing, engineering, and manufacturing hydrogen-related equipment, Chart now provides customers with all process technologies and major equipment across the entire gaseous and liquid hydrogen value chain.

“Our focus is on delivering flexible, scalable systems that help our customers adapt and lead – no matter where they are on their energy or sustainability journey”

Jillian Evanko, CEO, Chart Industries

THE CORE STRENGTH OF THE COMPANY

The vast and fascinating field of cryogenics is at the foundation of what Chart does – and it continues to be a core strength across both established and emerging markets.

“Our cryogenic systems support industrial gas storage and distribution, LNG applications, and energy infrastructure around the world. These are long-standing areas of expertise where we continue to innovate, scale, and serve a global customer base,” Evanko declares.

At the same time, the engineering and manufacturing capabilities that serve traditional energy and industrial gas markets are also enabling newer technologies – from hydrogen mobility and aerospace to carbon capture and even clean fuels for marine and aviation.

“For example, we’ve supported rocket launches with liquid oxygen tanks, enabled liquid hydrogen systems for space and trucking, and delivered ultra-large tanks for high-capacity storage applications,” she adds.

“What sets our portfolio apart is the breadth of solutions we offer – from tanks, heat exchangers, fans, compressors, trailers, and vaporizers to complete integrated systems – and our ability to tailor those solutions to each customer’s needs.”

BUILT TO LAST

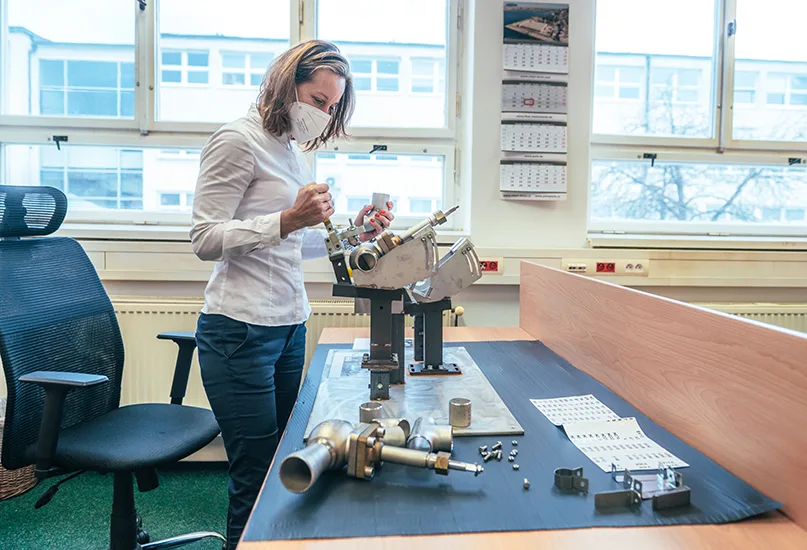

Within its substantial and varied portfolio, Chart’s bulk cryogenic storage systems are custom-engineered to meet application specifications for its clients.

The company’s complete system solution package ensures quality liquid or gas, which is used to keep processes operating at peak efficiency. Built for long-term integrity and industry-leading efficiency, these systems give clients the highest performance at the lowest operating cost.

Each Chart tank is engineered with a high degree of standardization for cost-efficient production and to keep delivery times short.

Parallel to this, a diverse range of bolt-on modular options ensure that its standard tanks cater to customer requirements, while further customization options are also available on request.

Boasting superior design and engineering prowess, Chart’s storage tanks feature state-of-the-art modular piping systems which combine high performance, durability, and low levels of required maintenance.

The key features of these tanks include a reduced number of joints which minimizes the risk of external leaks and facilitates simplified installation, as well as a comprehensive range of safety features to afford maximum protection for operators and the equipment itself.

Additionally, they possess easy access to control valves and instrumentation, meet seismic requirements, boast unrivalled engineering and manufacturing capacity, have world-class facilities strategically located in centers of demand, and Chart now leverages a dedicated range for the storage of CO2.

Engineered, manufactured, and tested in accordance with all major international design codes and associated regional requirements, these impressive products are truly engineered to excel and built to last.

CRYOGENIC TRANSPORT TRAILERS

Cryogenic transport trailers are specialized vehicles designed for the safe and efficient transportation of materials at extremely low temperatures, typically below -150 degrees Celsius (°C).

These state-of-the-art trailers are essential for industries such as healthcare, energy, and food production, where cryogenic liquids need to be transported safely and securely.

Different transport trailers are designed for specific gases and distances, with features such as a reinforced chassis for overcoming challenging road conditions and optimized designs for maximum payload.

Chart’s cryogenic trailers utilize multi-layer vacuum super insulation and other advanced technologies to maintain the necessary low temperatures and keep them at a constant and ideal level during the course of transit.

Crucially, these trailers are engineered to withstand the high pressures and extreme temperatures associated with cryogenic liquids, meaning Chart ensures safe and reliable transportation every time.

With engineering and manufacturing capabilities now stretching across three continents, Chart offers trailers, semi-trailers, swap bodies, liquid tube trailers, and railcars for the safe and efficient distribution of liquid gases including nitrogen, oxygen, argon, CO2, hydrogen, natural gas, and more.

As well as these standard liquid gases, a range of transport solutions for liquid nitrous oxide, ethylene, propane, butane, butadiene, and ethylene oxide are available on request for Chart’s customers.

Leveraging unrivaled expertise and exceptional pedigree in this enormous field, Chart manufactures its cryogenic trailers across the US, Europe, and China.

Furthermore, Chart’s engineers dedicate themselves to working with clients to determine the best configuration for their specific requirements.

Meanwhile, regardless of manufacturing location, all equipment is built to the same high-quality standards and in accordance with all associated relevant pressure vessel and stringent transportation codes and regulations.

NITRO INNOVATION

In recent years, Chart’s growing plethora of products have found a way to penetrate countless new sectors and markets across the globe.

If you’ve ever sat back and enjoyed a refreshing nitro beer, you can thank Chart’s frost-free, vacuum-insulated liquid nitrogen equipment for making that possible.

A nitro beer is a recent innovation that is primarily carbonated with nitrogen gas instead of the more common CO2, resulting in a noticeably smoother taste and a dense, cascading head.

Nitrogen is less soluble in liquid than CO2, meaning it forms smaller, more numerous bubbles.

Popular examples of nitro beers within this market include Guinness, which has popularized the use of nitrogen in stout beers, and various other beers and porters that utilize this technique.

Furthermore, many of the Chart’s customers are global household names – from Starbucks, which uses the company’s liquid nitrogen dosing technology for beverages like its Nitro Cold Brew, to Viking Cruise, which is exploring using hydrogen fuel cells with their ocean vessels, and ExxonMobil, which is using Chart’s state-of-the-art liquification technology in Northern Mozambique at the Rovuma LNG project.

“Our company has become particularly adept at taking old-school designs and equipment and transferring these concepts into new and emerging markets,” Evanko explains.

This expertise undoubtedly stems from over 157 years of hydrogen design and equipment building.

“During the COVID-19 pandemic, many companies became more focused on sustainability and the future of the world, so having this amount of hydrogen experience gave us a great jumping-off point to be able to serve these different end markets,” she continues.

SOCIAL SUSTAINABILITY

For Evanko, an element of the business which she sees as of vital importance is that of social sustainability, a concept that the company endeavors to uphold to the highest possible standards.

“We understand that the more variety we have in our perspectives and ideas, the more successful we are. As such, we are actively ensuring that all levels of the Chart family look like the societies we live in,” she tells us.

The company’s commitment to equity is evidenced by its diverse board of directors, with 40 percent of its current directors being female.

People are at the heart of the company, and they must be taken care of. As such, Chart looks after its ‘cool communities’ – referring to cryogenics, where it operates in many interesting locations.

“Every seven days, I send a daily spotlight out to our whole organization highlighting a team member or a group of our team members that has done something exceptional, or even just something kind or related to our key themes,” she continues.

‘Cooler By Design’ is more than just a tagline for the company. Whether it’s volunteering together through its Giving Back Program or team members competing in some friendly competition through the many fun activities on offer, Chart has perfected the art of enjoying each other’s company and having fun as it makes incredible results happen while ensuring that there is a healthy and enjoyable work culture.

“Some weeks, we host Motivational Mondays, which is put together by our teams and built around improving overall health, making sure our staff have a good work-life balance. We ensure they are taking care of their mental health and encourage them to spend more with their families.”

Chart also leverages a slate of geographically specific programs across all of its regions globally, as the company remains conscious of giving back to the communities it serves.

UNVEILING TEDDY 2

In the US, Chart’s new cryogenic facility in Theodore, Alabama (AL) was unveiled in March 2024.

The plant can manufacture the world’s largest shop-built cryogenic tanks with a capacity of up to 1,700 cubic meters (cbm).

These large tanks are used to store liquid gases including hydrogen, oxygen, and LNG for industries including aerospace, clean power, marine, gas-by-rail, and many others in the ever-expanding science and decarbonization sectors.

Known affectionately as “Teddy 2” because it’s the company’s second facility in Theodore, the facility has an optimal location, including direct access to waterways and railways which are key in providing customers with lower freight costs and faster transportation to site.

The expansion has also contributed significantly to local job creation and economic development efforts for the state of AL and its citizens.

“We were thrilled to officially expand our presence in Theodore with the ability to offer the world’s first shop-built cryogenic tanks of this scale,” Evanko recalls.

“This expansion further supports our customers through increased capacity and scale as well as lower freight costs and shorter lead times. We look forward to continuing to hire from the strong, skilled workforce in AL,” she prides.

BREAKING RECORDS AT SEA

Chart was recently pleased to announce a major milestone for the company and indeed the broader industry with the successful shipment of the first two jumbo cryogenic tanks built at the Teddy 2 facility.

Each with an impressive capacity of 1,700 cbm, they are considered to be the largest shop-built cryogenic tanks ever produced.

Made to support next-generation space launch infrastructure, these tanks reflect the growing demand for large-scale liquid gas storage across a wide range of emerging applications in aerospace, clean energy, maritime and carbon capture.

In addition to increased storage capacity, the process of shop building reduces on-site construction and facilitates modularization, thereby reducing overall project cost, schedule, and risk.

The expansion has also contributed to local job creation as well as significant economic development and is consistent with the region’s ambitions as an innovation hub for cleantech.

BUSINESS EXCELLENCE

What continues to set Chart apart is that the company is not just an equipment provider – it consistently delivers engineered solutions across a wide range of applications, tailored to the specific requirements of customer needs.

“We combine rotating and stationary equipment with process expertise to solve complex energy and industrial challenges,” Evanko explains.

As such, Chart’s molecule-agnostic approach to its operations is another key differentiator.

“We don’t compete with our customers in molecule production. Instead, we focus on enabling infrastructure across hydrogen, LNG, CO2 capture, water, biogas, and more, regardless of the molecule in play,” she adds.

The company also invests in R&D for cryogenic systems, carbon capture, and hydrogen technologies, amongst other areas.

This innovation, combined with a flexible manufacturing footprint and Chart Business Excellence – a unified approach to operations, pricing, and efficiency – allows it to move quickly without sacrificing even a fraction of quality or performance.

“Finally, we maintain strong proximity to our customers globally, with facilities and service operations across the globe. That local presence, combined with more than 170 years of technical expertise and a culture that prioritizes people and safety, allows us to act as a true partner – not just a supplier.”

Like many companies, Chart has had to navigate supply chain constraints, inflationary pressures, and global uncertainty.

“What helps us manage these challenges is our diversified footprint, strong supplier and customer relationships, and an innovative culture.

“We continue to localize manufacturing where needed, lean into flexible production models, and use our Chart Business Excellence approach to drive efficiencies across operations,” Evanko reveals.

“We combine rotating and stationary equipment with process expertise to solve complex energy and industrial challenges”

Jillian Evanko, CEO, Chart Industries

CHART’S ONGOING PROJECTS

One partnership Evanko is especially keen to highlight is Chart’s global master service agreement with ExxonMobil, including its ongoing work supporting the Rovuma LNG project in Mozambique.

“We are proud to expand our relationship with ExxonMobil through this enabling agreement. Chart’s industry-leading LNG technology, including our cold boxes and IPSMR® process, aligns with ExxonMobil’s commitment to efficient, scalable, and reliable LNG solutions,” she outlines.

“This agreement further strengthens our role as a trusted partner for ExxonMobil’s energy initiatives worldwide.”

In less than two decades, Chart has made a significant impact on the global LNG industry with its IPSMR® liquefaction technology.

Having curated a formidable reputation within the sector for its decades-long expertise with brazed aluminum heat exchangers, the company has quickly secured a leading position in the mid-scale segment.

With 29 million tons per annum of LNG liquefaction across operational and under-construction facilities, Chart has expertly established strategic partnerships with industry leaders like New Fortress Energy, Wison New Energies, Fluor Corporation, JGC, and various other international oil and gas and engineering, procurement, and construction (EPC) companies.

In the hydrogen market, Chart has delivered state-of-the-art equipment for the world’s largest hydrogen refueling station in China, supported the first green steel project in Sweden, and is enabling liquid hydrogen systems for marine and aviation markets.

“Our broad scope covers the full hydrogen value chain – from liquefaction and storage to transport, fueling, and end use – which allows us to serve a wide range of customers and end markets.”

Elsewhere, on the carbon capture front, Chart is advancing a number of initiatives across different industries and scales.

One example is its partnership with Bloom Energy (Bloom), in which the company is working together on an integrated solution that captures CO2 directly from Bloom’s high-efficiency fuel cells.

“What makes this partnership unique is how it combines commercially available technologies to make carbon capture more accessible and cost-effective. We’re also collaborating with Bloom on emerging opportunities in the data center space, where energy efficiency and emissions reduction are becoming critical priorities,” Evanko enlightens.

Parallel to this, across its portfolio of LNG projects, Chart is continuing to support a growing number of infrastructure projects globally – providing leading liquefaction, storage, and fueling systems that help meet near-term energy needs while enabling a lower-carbon future.

“Our full lifecycle capabilities range from liquefaction start-up to service, spares, and retrofits.

“One thing we remain very proud of is that all of these efforts reflect the same core principle – enabling our customers to move forward with practical, scalable solutions that balance performance, cost, and sustainability.”

AEROSPACE HAS LIFT OFF

Chart is also trusted supplier of cryogenic equipment and engineered systems to the aerospace industry.

Products and systems include cryogenic rocket propellant storage tanks, vacuum-insulated transfer piping, high-pressure pumping systems, knock-out drums, and deluge systems.

To date, the company has been integral in achieving operational success for its customers switching from RP-1 to LNG propellant, while it also provides on-pad storage of liquid oxidizers and upper-stage liquid propellant.

“We have been designing, building, and testing advanced cryogenic system equipment for more than half a century.

“Our team works closely with each customer to ensure that systems are designed in accordance with their requirements, function at their peak performance, and minimize risk to operators,” Evanko tells us.

“Built for long-term integrity, Chart system components and product designs provide the highest level of performance at optimal operating costs,” she asserts.

GOING WITH THE FLOW

In June 2025, Chart announced an all-stock merger of equals with Flowserve Corporation (Flowserve).

Flowserve is one of the world’s leading providers of fluid motion and control products and services. Operating in more than 50 countries, the company produces engineered and industrial pumps, seals, and valves, as well as a range of related flow management services.

“This combination takes our strategy to the next level – creating a differentiated leader in industrial process technologies with a broader portfolio, greater scale, and even more opportunity to serve customers across high-growth markets,” Evanko passions.

“Flowserve brings deep expertise in flow control, and when combined with Chart’s leadership in thermal technologies, we’ll be able to offer fully integrated systems and solutions.

“That means our customers can benefit from project streamlining, shorter lead times, and more efficient process design – particularly in complex, multi-technology applications,” she says.

Furthermore, this merger of equals also aims to enhance Chart’s aftermarket, service, and repair capabilities, expanding the company’s geographic presence and strengthening its balance sheet by accelerating deleveraging.

“We see clear cost and commercial synergy opportunities with this merger of equals, and we’re excited about the long-term potential to return value to shareholders,” Evanko gushes.

Most importantly, the two sets of teams across both companies are energized about what this means for the future of each business.

“By bringing together our complementary technologies, commercial pipelines, and digital capabilities, we’re creating a platform that’s positioned to accelerate innovation, strengthen customer partnerships, and drive long-term growth.”

Together, they are expected to have an enterprise value of approximately $19 billion based on the exchange ratio and the closing share prices for Chart and Flowserve as of 3rd June 2025.

With an installed base of more than 5.5 million assets in more than 50 countries, the combined company will expertly address the full customer lifecycle from process design through to aftermarket support.

STRATEGIC AND FINANCIAL BENEFITS

There are numerous strategic and financial upsides to the merger of equals for both Chart and Flowserve.

Firstly, with a comprehensive suite of world-class, differentiated solutions, it seamlessly brings together Chart’s leading expertise in process technologies across compression, thermal, cryogenic, and specialty solutions alongside Flowserve’s leading capabilities in flow management.

Combining digital platforms that underpin this full suite of solutions will enable further opportunities to differentiate solutions, offering a comprehensive digital overlay, including monitoring and predictive capabilities.

Elsewhere, the combined company will boast leading capabilities across countless areas including industrial gases, data centers, space, transportation, carbon capture, energy, power generation, nuclear, chemical, LNG, water, mining, and minerals.

As such, with this wealth of capabilities, the combined company will be more predictable and resilient.

A further benefit is that it will have significant recurring revenue streams, with a global installed base of more than 5.5 million assets and 42 percent of total combined revenue from aftermarket and service.

Chart and Flowserve expect to grow the aftermarket businesses by offering enhanced services and solutions to customers through an expanded global installed base and broad geographic reach.

Upon closing, the combined company board of directors will comprise 12 members – six each from Chart and Flowserve – with Evanko proudly serving as Chair of the Board.

DEDICATED TO SUSTAINABILITY

Across each individual facet of the company, sustainability is central to who Chart is as a business and what it does.

“Our products and numerous technologies across our portfolio support our customers’ emissions reduction, energy efficiency, and decarbonization initiatives”

Jillian Evanko, CEO, Chart Industries

“We provide the state-of-the-art infrastructure that enables lower-carbon fuels, scalable CO2 capture, water treatment, and cleaner industrial processes,” she follows up.

Beyond its products and solutions, Chart also holds itself accountable internally. This includes environmental, social, and governance (ESG)-linked compensation, supplier sustainability reviews, and operational efficiency programs across its entire global footprint.

“Sustainability drives innovation, strengthens our commercial pipeline, and increasingly, it’s what our customers and investors expect. We don’t view it as a separate strategy – it’s fully embedded in our culture and how we operate and grow as a business.”

ONE COHESIVE TEAM

Across the entire spectrum of Chart’s operations, every individual team member is encouraged to fulfill their potential, while their culture, identity, and experience is respected and valued.

“We understand that the more variety we have in our perspectives and ideas, the more successful we are. We not only take strides to give Chart team members the resources they need to make of their career whatever they dream it, but also ensure they feel good while doing it,” Evanko confirms.

“Our people are the reason we’re able to do what we do. From welders and machinists to engineers and sales teams, there’s a shared sense of purpose across the organization.”

One of Evanko’s personal priorities is creating an environment where people feel valued, heard, and are given access to a multitude of exciting career opportunities.

To date, Chart has launched several key programs focused on career and talent development and mentorship – including its numerous employee resource groups (ERGs) such as Chart Network of Women, which aims to empower women both personally and professionally.

As well as this, the company is proud of its Chart Rise and Prime initiative, created for young and emerging professionals as well as seasoned, experienced professionals focused on mentorship and Chart veterans.

“In 2024, each of our talent development programs expanded and continued to grow – including our Emerging Leaders Program, Rotational Engineering Program, Operational Leaders Program, Global Diversity and Inclusion Committee, Global Sustainability Committee, and Global Welding Council,” Evanko lists.

“We also hit record participation in our Internship Program this summer as we welcomed 38 interns, ranging from high school to graduate school level,” she acclaims.

Of the 38 interns, over a quarter are returning – including three who are with the company for a third year running.

“As both a leader and a working mom, it’s important to me that we show the next generation that manufacturing is a place where they can build meaningful, exciting careers.”

RESPONSIBLE OPERATIONS

Corporate social responsibility (CSR) is built into every facet of how Chart operates.

“Through our Giving Back Program, the company offers every team member globally one extra day of paid time off per year to support a charitable initiative of their choosing as well as funding-matched opportunities up to $250,” Evanko grins.

Meanwhile, Chart supports global and local giving programs, STEM education, and environmental initiatives across its numerous locations.

“Our teams regularly lead efforts such as tree planting and ‘Adopt-a-Highway’ initiatives, volunteering at food banks and other charities, as well as supporting disaster relief and environmental conservation programs – not because they have to, but because it’s part of our business-wide culture,” she explains.

“Internally, we’ve launched initiatives like our Global Diversity and Inclusion Committee, our ERGs, which are active in over 10 countries across our global organization, and ESG-linked performance targets at leadership level.”

In addition to this, Chart is also a proud participant of the United Nations (UN) Global Compact.

“CSR for us is about making a tangible, lasting impact in the communities we serve and empowering our people to lead that effort,” assures Evanko.

“CSR for us is about making a tangible, lasting impact in the communities we serve and empowering our people to lead that effort”

Jillian Evanko, CEO, Chart Industries

FUTURE BUILDING

Moving forward into a bright future, Evanko is keen to emphasize that the next phase for Chart – especially following its merger of equals with Flowserve – is about scaling smarter, growing faster, and delivering even greater value across thermal and flow technologies.

“One of the most compelling aspects of this exciting new combination is the ability to offer customers a single-point supplier for integrated systems, which streamlines projects, reduces complexity, and improves efficiency across the board,” she excites.

“As we level up, we will continue to focus on execution, safety, and innovation – and we’re deeply committed to creating impact for our customers and opportunities for our team members.”

As such, Chart has meticulously developed and grown to become a company that has combined deep technical expertise with adaptability and an entrepreneurial culture – supporting traditional infrastructure while also helping to accelerate the shift to cleaner, more efficient systems.

“Our major upcoming and ongoing priorities are continuing to drive results, focusing on securing a high level of safety, scaling solutions across our end markets to better support our customers, investing in people, and successfully integrating our merger of equals with Flowserve,” Evanko follows up.

Today, with a successful culture built on safety, integrity, innovation, and kindness, the company wants to be remembered not just for the solutions it has historically delivered, but for the way it empowers its people and has made a lasting impact on the industries and communities it serves.

From the early days of pioneering heat transfer solutions for cryogenic liquefaction to today’s green energy challenges, Chart has been there every single step of the way and will continue to build on its already impressive legacy and considerable influence and contribution to this burgeoning industry.

“The future we’re carefully building is one where engineering, manufacturing, sustainability, and strong industry leadership come together to make a meaningful difference,” Evanko concludes firmly.

CHART INDUSTRIES PARTNERS