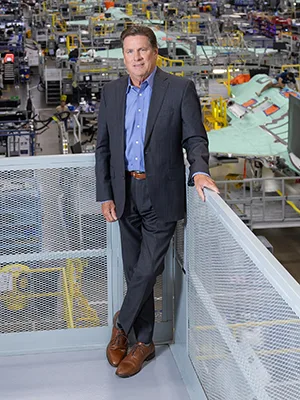

Robert Powell, Vice President of Global Production Operations at Lockheed Martin Aeronautics, outlines the company’s latest fighter jet developments – particularly the F-35 Lightning II program – alongside its mission-driven digital transformation and operational improvements as high-performing defense products become increasingly crucial in today’s geopolitical landscape.

SECURING THE SKIES

At a time when the US and its allies require highly capable yet affordable defense products more than ever, Lockheed Martin Aeronautics’ work has become increasingly critical as it continues to develop, manufacture, and deliver world-class aerospace technologies.

“We find ourselves facing technological advancements which are happening faster than ever,” opens Robert Powell, Vice President of Global Production Operations.

As a company that actively leverages artificial intelligence (AI) integration, model-based engineering, and advanced production technologies, it is well placed to meet the growing demand for superior defense capabilities such as those found in its F-35, F-22 Raptor, and F-16 Fighting Falcon fighter jets, as well as its C-130J Super Hercules airlifters.

In addition to the work it is doing in the US to produce F-35s, F-16s, and C-130s, Lockheed Martin Aeronautics is also seeing increased opportunities to work with allies at its co-production facilities.

In June this year, for example, the company supported the opening of an F-35 forward fuselage facility in Finland with the country’s defense, security, and aviation company, Patria.

In July, meanwhile, Rheinmetall – Germany’s largest arms manufacturer – began F-35 center fuselage co-production at its new facility in Weeze.

“Our programs – particularly the F-35 platform – are global enterprises that not only promote national security for the US and its allies but also provide significant economic benefits through job creation, innovation, and growth in the aerospace sector,” he notes.

THE PATH TO LEADERSHIP

Having joined Lockheed Martin as an F-16 mechanic on its production floor in Fort Worth, Texas, Powell developed a first-hand understanding of the company’s commitment to employee development.

“My start as a mechanic gave me great insight into the work itself and also into union engagements. The floor mechanics and I still have a great working relationship because I’ve done the work they are doing,” he says.

As such, Powell was able to utilize his skills and knowledge as a mechanic to better represent the touch labor workforce through leadership.

Nominated to join a six-month Supervisor Assessment and Development Program just a year after starting at the company, Powell’s first leadership role was as a supervisor for F-16 production.

“The program’s name describes exactly what it does – equip production floor employees with the tools and knowledge needed to grow into supervisory and leadership roles,” he adds.

During his early years with Lockheed Martin Aeronautics, Powell also completed a bachelor’s degree in business management – graduating with honors – while working full-time in a high-pressure environment and balancing a family.

Over the years, he has completed many internal and external leadership development programs, including the Senior Leadership Development Program at Carnegie Mellon University and a Lockheed Martin Executive Assessment and Development Program.

“My production floor experience, coupled with my degree and the leadership development programs I completed, gave me the opportunity to work in positions of increasing responsibility across Aeronautics Operations and the F-35, F-22, and F-16 platforms, spanning all phases of our products’ lifecycles,” Powell shares.

In this way, he has led many transformative efforts for Lockheed Martin Aeronautics such as the transformation of its Fort Worth facility from F-16 to F-35 production and the establishment of 15 major production sites around the world.

These include the introduction of brand-new F-16 production facilities in Greece, Israel, Poland, and India, and the start-up of production systems for the F-35 in Italy, Israel, Japan, and Finland.

“By surrounding yourself with talented, trustworthy people and giving them the autonomy to do meaningful work, you create an environment where innovation, ownership, and results thrive. Never stop caring about people”

Robert Powell, Vice President of Global Production Operations, Lockheed Martin Aeronautics

UNMATCHED STEALTH

Combining stealth, speed, advanced sensors, and unmatched connectivity all in one platform, the F-35 stands in a class of its own as the world’s most lethal, survivable, and connected fighter aircraft.

Its aligned edges, reduced engine signature, internal carriage of weapons and fuel, and embedded sensors all contribute to its uniquely low observable stealth performance.

“With stealth designed in from day one, the F-35 has an unmatched ability to enter contested airspace and evade enemy detection,” Powell outlines.

The F-35 also has the most advanced sensor suite of any fighter in history which includes the Active Electronically Scanned Array (AESA) radar, Distributed Aperture System (DAS), and Electro-Optical Targeting System (EOTS).

The F-35’s advanced sensor fusion enables pilots to draw information from on-board sensors to create a single integrated picture of the battlefield that greatly enhances awareness and survivability.

Advanced electronic warfare capabilities, meanwhile, allow the aircraft to locate and track enemy forces, jam radars, and disrupt attacks, while one of the world’s most powerful fighter engines – the Pratt & Whitney F135 – enables it to travel at a top speed of Mach 1.6.

Going forward, all variants of the F-35 will have the potential to carry Joint Air-to-Surface Standoff Missiles (JASSM) or Long-Range Anti-Ship Missiles (LRASM) – both produced by Lockheed Martin Missiles and Fire Control – providing increased reach, lethality, and survivability against heavily protected strategic targets and increasing the ability to deter near-peer adversaries.

“The F-35 serves as an information and communications gateway, sharing its operational picture with ground, sea, and air assets,” he comments.

Highly advanced helmet technology projects information such as airspeed, heading, altitude, targeting information, and warnings within the helmet’s visor – as opposed to the traditional heads-up display – greatly reducing the pilot’s workload and increasing responsiveness.

“Simply put, the F-35’s capabilities enable the pilot to enter an airspace and complete his or her mission before the enemy even knows it’s coming, enabling the aircraft to maintain air dominance today,” Powell says.

AHEAD OF THE CURVE

Currently transforming end-to-end business processes and systems across the company, Lockheed Martin seeks to deliver speed and agility for its customers, enabling them to stay ahead of the rapidly evolving threat environment.

Through its mission-driven transformation program, Lockheed Martin’s OneLM Transformation (1LMX), the company is creating a model-based enterprise with a fully integrated digital thread throughout the entire product lifecycle – from design and build through to sustaining the product.

“We are using digital twin technology to create a dynamic virtual replica of physical systems, reducing costs by lowering our reliance on physical prototypes while increasing speed to delivery – both of which are important to our company and “customers,” Powell states.

Lockheed Martin’s digital transformation capabilities include model-based digital engineering which optimizes and links design, manufacturing, and sustainment teams on a common digital thread to save costs and speed up program lifecycles.

A company-wide software factory, meanwhile, is utilizing Development, Security, and Operations (DevSecOps) approaches and enabling the fast development and continuous deployment of software to advance customers’ missions.

“Company-wide investments in process reinvention, business system modernization, 5G networking, cybersecurity, and cloud-based technologies are laying the foundation for transformational capabilities,” he comments.

“We’re building global infrastructure that will enable us to share data instantly and securely, and AI-powered predictive analytics to glean insights that advance performance from factory to field.”

Lockheed Martin is also revolutionizing factories with smart tools, connected machines, networked supply chains, and augmented and virtual reality (AR/VR) for technicians that speed up production and improve quality.

“We are committed to delivering air superiority that enables full-spectrum dominance, supports national defense priorities, and ensures the safety of our allies and partners across the globe”

Robert Powell, Vice President of Global Production Operations, Lockheed Martin Aeronautics

LEADING WITH EXCELLENCE

Powell’s current role includes developing Lockheed Martin’s functional strategies to support all Aeronautics lines of business.

His organization includes production engineering; production control; fabrication and tooling; industrial engineering; shop floor training; environment, health, and safety; facilities; and all international production operations.

“My organization of about 6,500 employees works to design and implement efficient production processes, while also creating or sourcing the necessary tools and equipment to bring those designs to life,” Powell says.

His team also optimizes workflows by analyzing and improving processes to increase productivity and reduce waste while ensuring the highest quality products and on-time delivery.

“It’s a challenging but rewarding role, and one that sees my team integrate across every program, throughout all parts of the business and the globe,” he adds.

To continue leading with excellence, Powell is guided by Lockheed Martin’s core values – to ‘do what’s right’, ‘respect others’, and ‘perform with excellence’ – simple but powerful principles that shape employees’ behavior and guide decision-making.

“I am so proud of our employees, who I see practice these values every day,” Powell says.

“The people who work at Lockheed Martin are uncompromising in the integrity of their work and always keep the mission in mind.”

‘Do what’s right’ represents the company’s commitment to the highest standards of ethical conduct in everything it does, with employees unafraid to raise their hands and speak up when they see something that doesn’t look right.

Recognizing that success depends on the talent, skills, and expertise of its people, ‘respect others’ has become a cornerstone of the company’s ability to collaborate across functions, programs, roles, leadership levels, and beyond.

‘Perform with excellence’, meanwhile, acknowledges the importance and impact of Lockheed Martin’s work.

“Ultimately, it emphasizes how the security of our nation and that of our allies depends on the quality and capability of the products and services we provide,” he adds.

A BRIGHT FUTURE

Lockheed Martin is pursuing the answers to its customers’ most pressing questions.

For example, it currently has a corporate-wide focus on ascertaining the solutions it can provide for the Golden Dome initiative.

“Earlier this year, President Donald Trump called for a new approach to homeland defense. Lockheed Martin answered the call as the nation’s leader in integrated air and missile defense who can build the most capable team to make the Golden Dome concept a reality,” Powell explains.

A layered defense shield, the Golden Dome initiative will include a system that detects, tracks, and intercepts incoming missiles before they reach US soil.

As the industry leader in defense with combat-proven layered defense solutions already in place, Lockheed Martin is uniquely suited to deliver on the criteria for Golden Dome.

“While we explore future needs, my most immediate role is ensuring our current programs deliver capabilities with unmatched quality to best serve those who serve,” he maintains.

Looking ahead, Powell reflects on his 39-year long career in leadership, his belief that people are always the most valuable resource, and how success is built on the strength of a team.

“By surrounding yourself with talented, trustworthy people and giving them the autonomy to do meaningful work, you create an environment where innovation, ownership, and results thrive. Never stop caring about people,” Powell advises.

The company’s ongoing goal for the future, meanwhile, is to continue to deliver for the customers who rely on its products – whatever their mission.

With a focus on connected, multi-domain operations, Lockheed Martin’s solutions empower military forces to maintain control of the air, outpace emerging threats, and achieve a decisive advantage in any mission.

“We are committed to delivering air superiority that enables full-spectrum dominance, supports national defense priorities, and ensures the safety of our allies and partners across the globe,” Powell confidently concludes.