As humanity sets its sights on the moon once more, NASA is launching a bold quest to establish a lasting presence beyond our planet, paving the way for future exploration and discovery. We delve into the manufacturing processes behind the Artemis II mission.

A GIANT LEAP FOR LUNAR AMBITIONS

Aiming to establish a permanent lunar presence, NASA is sending a crewed spacecraft to orbit the Earth’s celestial natural satellite for the first time in over 50 years, marking a significant step in space travel.

The historic Artemis II mission is crucial for testing the systems and hardware required for human space exploration and is scheduled to occur as soon as spring 2026. It will follow the unmanned Artemis I and act as a stepping stone to return to the moon’s surface.

Four astronauts are preparing to embark on a 10-day mission, launching from Florida, US. Upon their return, they will splash down in the Pacific Ocean.

The crew consists of NASA astronauts Reid Wiseman, Victor Glover, and Christina Koch, along with Jeremy Hansen from the Canadian Space Agency. Whilst they will not land on the moon, they will be the first team to venture beyond low Earth orbit since Apollo 17 in 1972.

The astronauts are set to travel 5,716 miles beyond the moon, and with the average distance between the Earth and the moon being 238,855 miles, though this distance varies throughout the moon’s orbit, this mission will take humans further into space than ever before.

Artemis II’s crew will serve as research subjects as they investigate how deep-space environments impact human health, examining factors such as radiation, immune responses, cognition, and sleep.

The programme is not just about returning to the moon; it is also about developing the technology, human knowledge, and operational experience needed for manned missions to Mars.

Essential technologies and equipment for the mission include landers, as well as habitation, mobility, communication, power, and thermal regulation systems, all designed to perform reliably in extreme lunar conditions.

Health evaluations will focus on the impact radiation exposure, isolation from Earth, dust exposure, and low gravity will have on humans, which are critical for long-duration Mars missions.

Operational procedures for time spent outside, resource management, and emergency responses will be developed and refined as Artemis II provides a more controlled environment than the Red Planet.

By iteratively testing and improving during the missions (especially Phase IV), NASA reduces risk, cost, and unknowns associated with Mars exploration.

Understanding what is effective and what isn’t on the moon therefore helps to accelerate humankind’s journey to Mars.

TO THE NEXT FRONTIER AND BEYOND

The manufacturing of the core stages for the Artemis II and III missions took place in New Orleans, US, at NASA’s Michoud Assembly Facility.

Engineers utilised friction welding to construct these stages, which will eventually enable the first woman, person of colour, and international partner astronaut to land on the moon. Currently planned for mid-2027, NASA will also make history by sending the first humans to explore the region near the lunar South Pole.

NASA collaborated with Boeing to oversee the precise assembly of the mission’s Space Launch System (SLS), whilst Lockheed Martin completed the Orion spacecraft for Artemis II and prepared it for transfer to NASA’s Exploration Ground Systems (EGS) team.

After successfully evaluating the spacecraft’s systems through ground testing and uncrewed flights, the Artemis II mission will subsequently validate Orion’s capabilities with a crew aboard.

The spacecraft features enhanced life support systems and a Launch Abort System (LAS) for crew safety. Additionally, it includes docking sensors and an experimental laser communication system.

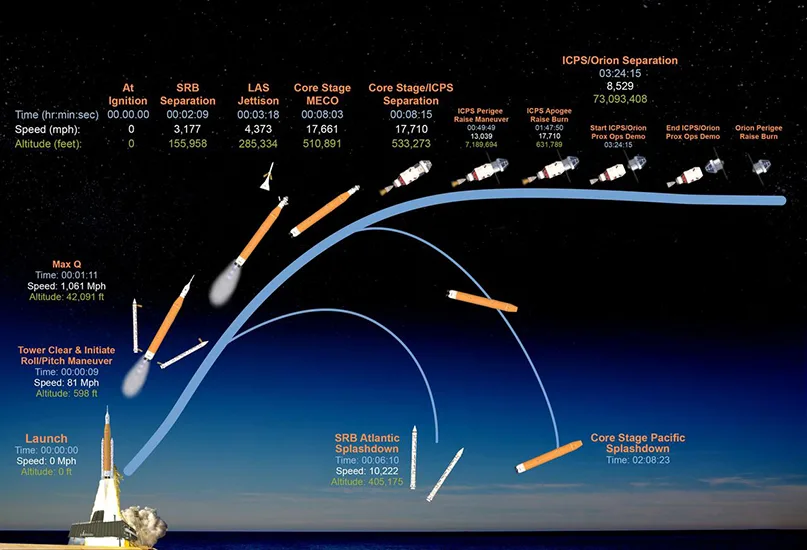

Orion will be launched on top of the SLS, initially propelled by solid rocket boosters, but after they are jettisoned along with the core stage, the Interim Cryogenic Propulsion Stage (ICPS) will assist in manoeuvring.

The spacecraft will then practice docking manoeuvres before executing a Translunar Injection burn, which sets it on its journey around the moon before safely returning to Earth.

Now that Orion is complete, Lockheed Martin has transferred it to the EGS team, where they will perform final preparations on the spacecraft, readying it for launch – a significant milestone that advances the organisation’s objective.

This is where the propellants and consumables, such as water and oxygen, are added, and the LAS and its protective fairings are installed.

Inside the Multi-Payload Processing Facility (MPPF) at NASA’s Kennedy Space Center, Orion is awaiting final integration and stacking with the SLS rocket. Eventually, the spacecraft will be transported to the Vehicle Assembly Building, where it will undergo final preparations for launch.

Meanwhile, NASA has recently integrated the stage adapter with the rest of the SLS rocket.

During the mission, the crew will evaluate the spacecraft’s performance, test its navigation and communication systems, and conduct a series of scientific experiments.

They will perform a rendezvous operation with the SLS upper stage, practising docking activities needed for future missions, including Artemis III.

The success of the mission will determine how soon NASA can launch Artemis III to land on the moon.

COOL INNOVATIONS AND MODIFICATIONS

The Avcoat heat shield used on the Orion spacecraft is one of the largest ablative heat shields ever constructed for a crewed spacecraft, designed to withstand extreme temperatures during re-entry and ensure the safety of astronauts.

There are current concerns regarding the heat shield material used, specifically Avcoat, which failed to perform as predicted during the Artemis I mission’s re-entry. The outer ablative layer generated in-escapable gas under heat, leading to internal pressure, cracking, and material loss, despite the safe temperatures inside.

Avcoat is designed to ablate safely, but insufficient venting resulted in increased pressure. This situation is critical because the thermal protection system must withstand extreme speeds and temperatures during re-entry, and any weakness poses significant risks, especially with astronauts on board.

The solution for Artemis II was not to replace the heat shield but to adjust the re-entry path and apply the lessons learned from previous missions.

NASA decided that the existing heat shield for Artemis II is acceptable, provided the re-entry trajectory is modified to minimise the time the shield spends in the problematic temperature and pressure range. This adjustment also affects how far Orion travels between entering the atmosphere and splashdown.

The re-entry trajectory influences the heating profile, including the entry angle, speed, atmosphere traversed, and the duration of exposure for critical components. By shortening the ‘skip entry’ or limiting the time spent in the atmospheric regime that caused gas entrapment and damage, engineers believe they can keep astronauts safe.

Additionally, since the heat shield is already attached, redesigning or replacing it would lead to significant delays. Thus, modifying the trajectory represents a lower-risk and more time-efficient solution.

Artemis II will serve not only as a test for carrying a crew around the moon but also as an evaluation of how to adapt to unexpected physical challenges – a hallmark of deep space mission design.

A LAUNCHPAD FOR LUNAR LESSONS

Lessons learned from Artemis I are being applied to future Artemis missions through enhanced shield manufacturing and stricter environmental control requirements.

For Artemis III and subsequent flights, modifications to the heat shield will include improved uniformity, controlled permeability – ensuring gases can escape as needed – and changes in manufacturing methods for the Avcoat layers.

More specifically, enhancements in the uniformity of the shield material will reduce weak spots, whilst proper permeability allows gas to vent rather than build up pressure.

Furthermore, other systems, such as life support and environmental control, are being upgraded.

Improved environmental control ensures the capsule can reliably support human life under stress. These adjustments are not mere superficial changes; they address the critical interplay of materials science, thermal dynamics, human safety, and mission architecture.

Laying the groundwork is crucial for future missions, which include Artemis IV, scheduled to deliver Lunar I-Hab to the first moon-orbiting space station, Gateway, in the autumn of 2028. This will be followed by astronauts on Artemis V, who will live and work on Gateway in preparation for human missions to Mars.

Artemis VI is expected to launch in 2031, building on the success of previous missions and igniting new possibilities in the vast cosmos, bringing the collective dreams of interplanetary travel, held by generations past and present, closer to reality.