As the manufacturing industry sees the onset of more advanced technologies, artificial intelligence (AI) poses improvements to automation within the sector. Theo Saville, CEO of CloudNC, tells us more about the company’s use of AI in its precision manufacturing processes.

- MACHINING STRATEGIES IN ONE CLICK

- Q&A WITH THEO SAVILLE, CEO, CLOUDNC

- How is CloudNC using AI to greatly accelerate the computer-aided manufacturing (CAM) programming of CNC machines?

- When did you launch CAM Assist, and what has uptake been like since the software hit the market?

- What advanced computer science techniques does CAM Assist use to generate these professional machining strategies?

- How will these advancements re-energise precision manufacturing companies struggling with rising costs and ageing workforces?

- Finally, can you tell us about the beta testing for 3+2 axis machining?

MACHINING STRATEGIES IN ONE CLICK

Over the years, the manufacturing industry has continued to see steady growth and an upward trajectory. Whilst this is a fantastic trend for expansion within the industry, the rate of production often struggles to keep pace with demand.

2023 saw AI evolve to influence our everyday lives. From ChatGPT and OpenAI for businesses and individuals, to operational optimisation for supply chains and factories, the onset of new AI technologies certainly increased societal productivity.

As such, the automation of the manufacturing sector has become a top priority going forward. Businesses and manufacturers alike recognise the benefits of AI and automated processes in their day-to-day activities, from optimising design and production functionalities to predictive maintenance and improving the speed of operations.

CloudNC, a UK manufacturing technology company, is a pioneer in this field, applying AI to the manufacturing process, allowing companies worldwide to programme the manufacture of parts and components more efficiently.

Theo Saville, CEO, discusses bringing one-click automation to computer numerical control (CNC) machining.

Q&A WITH THEO SAVILLE, CEO, CLOUDNC

How is CloudNC using AI to greatly accelerate the computer-aided manufacturing (CAM) programming of CNC machines?

Theo Saville, CEO (TS): CloudNC is a technology company reinventing precision manufacturing by automating CNC CAM programming, enabled by data and experience from our high-spec factory.

We’re backed by investors including Autodesk and Lockheed Martin, and we’re applying AI to accelerate global component manufacturing.

People think making parts and components is automatic, but it’s not. Almost everything that we use is made manually by experts – which requires considerable time, effort, and resources.

CloudNC’s technology accelerates and automates precision manufacturing and makes it more efficient, reliable, and accessible.

It completes much of the difficult, manual work involved with making a component – whether that’s programming a machine, creating a schedule for a factory to produce it, or selecting the correct tools for the job and how best to use them.

As a result, manufacturers become much more productive. Experts spend less hours on time-consuming chores, and instead add value by applying their knowledge to complex tasks.

Meanwhile, less-experienced workers receive a head start, guided by advanced tools that help them to resolve new challenges.

These advances re-energise manufacturing sectors struggling with rising costs, ageing workforces, and competition from globalisation, keeping the costs of everything down for all.

What we are doing is an important step towards the manufacturing ideal, enabling products to be made with a single click.

When did you launch CAM Assist, and what has uptake been like since the software hit the market?

TS: We released CAM Assist in June 2023, and it’s now being adopted by hundreds of global users.

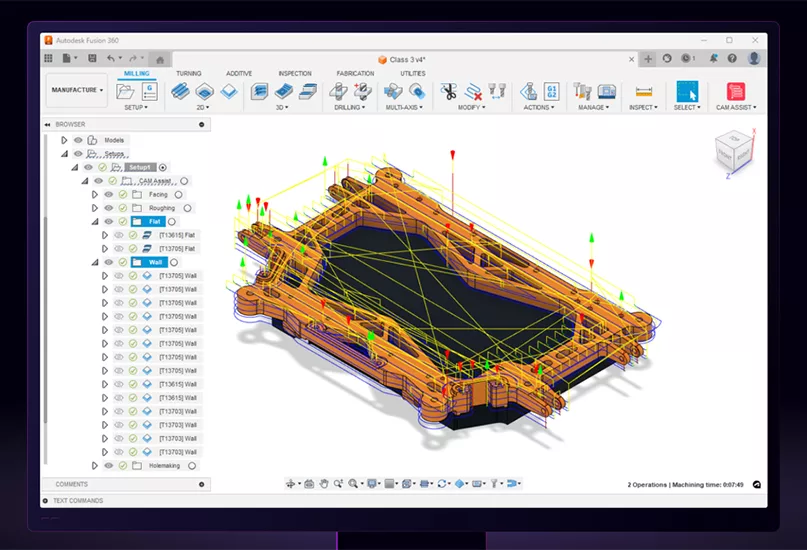

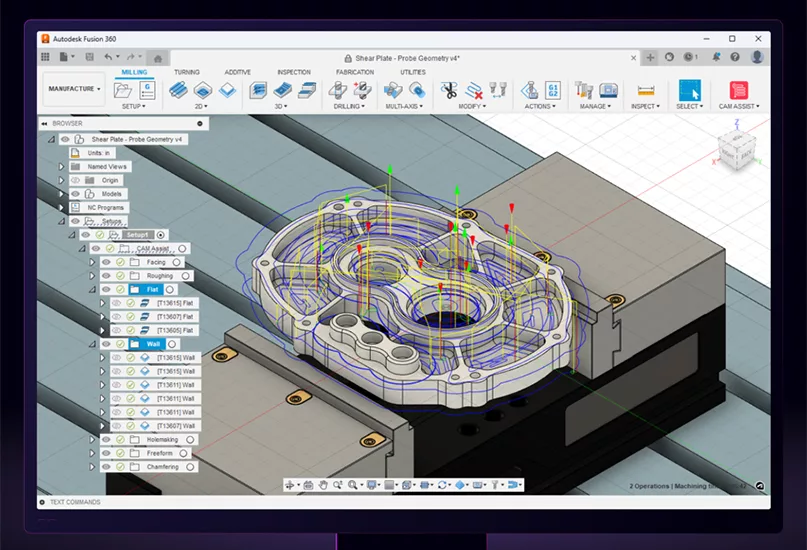

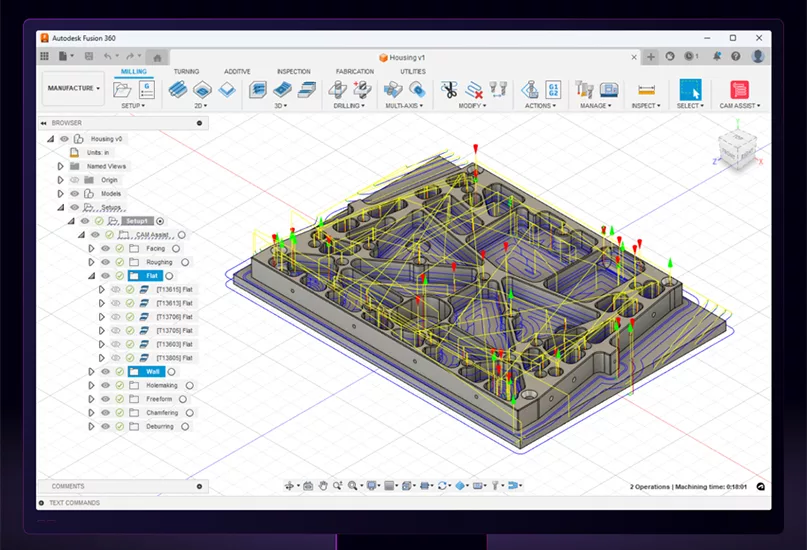

Currently available as a plug-in within Autodesk’s Fusion 360 software platform (but coming soon to other platforms), CAM Assist uses advanced computer science techniques to generate professional machining strategies for 3-axis parts in seconds, which could take CNC machine programmers hours or even days to manually create.

As a result, the amount of time it takes to programme a CNC machine to make a component – a bottleneck in many factories due to a global skills shortage – is greatly reduced compared to the previous manual programming process.

That gain enables manufacturers using CAM Assist to save hundreds of production hours and shorten lead times.

What advanced computer science techniques does CAM Assist use to generate these professional machining strategies?

TS: CAM Assist uses advanced computational optimisation and AI inference techniques to rapidly determine a professional strategy and the toolset needed to manufacture a part, along with the most appropriate cutting speeds and feeds from the user’s library.

As a result, a user today can upload a 3D model of a 3-axis component and the software determines the appropriate milling tools needed from those available, and how they will be used.

In seconds, CAM Assist drafts the code required to instruct a CNC machine how to make it, within the user’s existing CAM platform.

How will these advancements re-energise precision manufacturing companies struggling with rising costs and ageing workforces?

TS: Manufacturing in many parts of the world is a declining industry, threatened by rising costs as well as global competition from factories overseas that don’t face the same overheads. However, it remains vital, not least because it still makes everything we need today.

Most people don’t realise that manufacturing is still heavily reliant on experts, but it is, and they are getting old; about half of precision machinists will have retired in 10 years, and almost all of them will be retired in the next two decades.

CAM Assist fills that skills gap with smart technology that helps everyone in the CNC process, saving skilled programmers production hours and upskilling junior workers much faster.

Essentially, we’re plugging the skills gap that exists within CNC machining (in fact, it’s a skills crisis!) with a smart application of cutting-edge coding that opens up enormous efficiency savings and gains.

Finally, can you tell us about the beta testing for 3+2 axis machining?

TS: Yes! In addition to coming soon to platforms like Mastercam, Siemens NX, and Solid Edge, CAM Assist is currently in beta testing for 3+2 axis machining, which will greatly increase the utility of the AI and enable it to make much more complex parts.

If you want to see how CAM Assist can change CAM programming forever, simply go to our website and give it a try!

Editor’s note: Many of the business leaders featured by Manufacturing Outlook continue sharing their insights on LinkedIn. For CEOs in the sector seeking to strengthen their online presence, visit Linkedin profile optimization.